An artifact for efficient furniture manufacturing

In recent years, the domestic demand for home decoration is huge, which has further promoted the quality and efficiency of furniture production equipment.

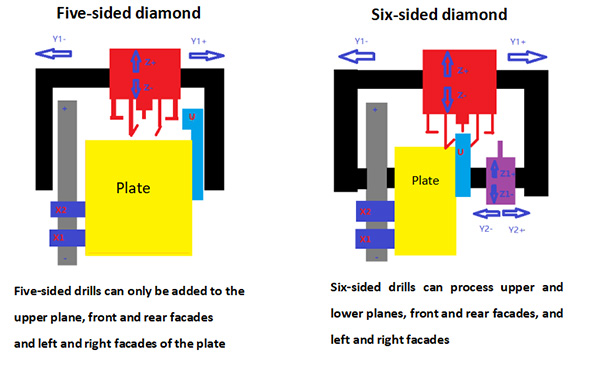

The main equipment in the production and manufacturing of daily furniture includes: Log processing machinery——Rotary cutting machine,Machinery for the production and processing of plates——Edge banding machine、Chainsaws, cutting machines, and furniture manufacturing machinery – CNC five-sided drills, six-sided drills, etc.

Customer requirements

In terms of furniture manufacturing, because the production efficiency of the old-fashioned five-sided drill cannot meet the manufacturing needs of customers, and the CNC six-sided drill can be clamped at one time and solve the characteristics of the drilling process of the six sides of the plate, the customer is ready to replace it with a CNC six-sided drill.

The main working principle of CNC six-sided drilling is that the programming technician converts the drawings of the plate to be processed into an NC program into the motion control system, which controls the servo operation of the upper

and lower tool magazine and spindle and each feed axis.

INVT solutions

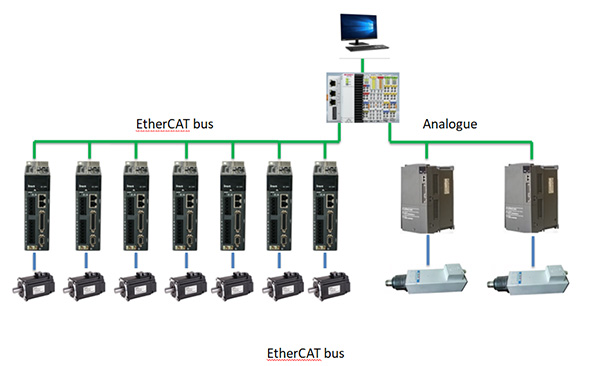

In order to make CNC six-sided drills efficient, stable and accurate, INVT provides customers with system solutions.The solution includes: EtherCAT bus system + DA200 servo + GD20 series inverter.

Scenario system diagram

In the actual application process, the program products have the following characteristics:

1) Excellent communication mode: DA200 series servo can dock with the mainstream EtherCAT bus system on the market, and the synchronization time of each axis is 1ms.

2)Excellent performance: speed response up to 2kHZ, maximize high-end mechanical properties.

3)Excellent positioning accuracy: equipped with 23-bit high-resolution encoder, more accurate positioning, the position origin of the power-off motor is not lost.

Customer benefits

1. High efficiency: fast running speed, up to 90m/min, production speed is more than 50% higher than traditional equipment.

2. Intelligent: flexible docking of the factory's production equipment, will not cause equipment update and waste.

3. High precision: one-time clamping can punch holes on six sides, and the hole position accuracy completed by one equipment is higher.

4.Easy maintenance: less wiring, easy to troubleshoot.

Programme summary

The popularity of CNC six-sided drilling is currently increasing and many customers will take note of this equipment when choosing CNC drilling equipment. CNC six-sided drills using INVISION technology are easy to operate, highly efficient and accurate, with a substantial increase in production speed compared to traditional equipment, making them very popular in the market.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.